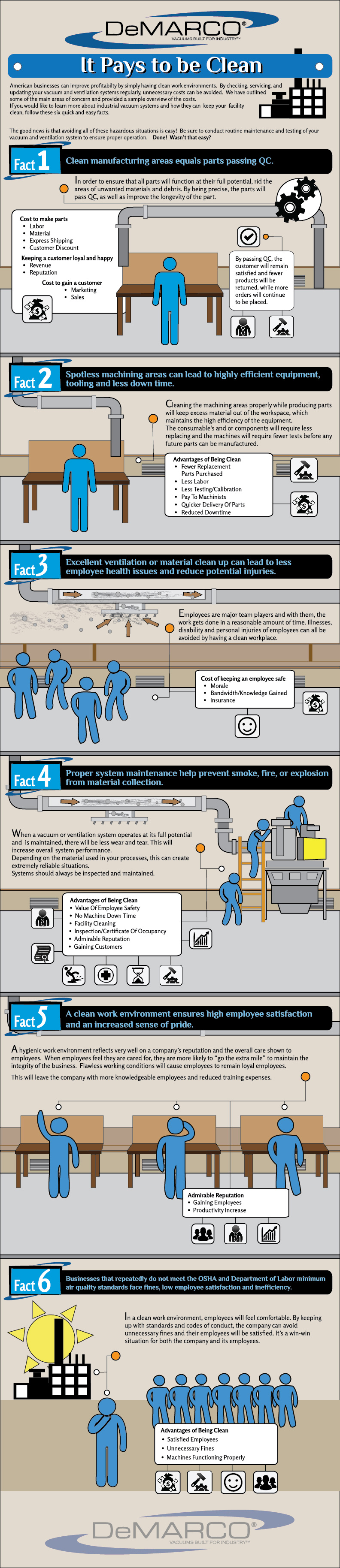

Good housekeeping is important in any workplace. In factories with processes that create combustible dust, however, ensuring good housekeeping and workplace organization should be a top priority. To keep employees safe and processes running smoothly, a regular schedule should be kept for cleaning up, safely removing and disposing of the dust. Yet, whenever a new initiative like this is undertaken, it is often difficult to sustain.

Reliable Plant recently addressed how starting an important initiative like this can often lose its importance over time. “This generally occurs because the expectation was created, but no follow-up was established,” Curtiss Quirin, the director of supply management for industrial supplies for Delphi Corp., wrote.

Quirin recommends the following key steps when starting a routine housekeeping program:

- Pick something important;

- Involve your people;

- Establish measurable requirements;

- Make it visible;

- Set up an audit frequency; and

- Have the discipline to stay on course.

“Before any new initiatives are started, you, as the leader, must decide what is important and be prepared to stay the course,” according to Quirin. “The goal is to set a standard and change behavior.”

When implementing a successful change initiative, bringing about the required behavioral changes needed to sustain the program is not easy. But if leadership picks an important activity – like the safety of employees and the structural integrity of the facility – and develops the discipline to stay the course, commitment to the new initiative should become easier and, ultimately, lead to improved safety, quality and productivity.

“Inspection requires not only the creation of a standard but also the discipline to observe and audit on a regular basis,” according to Quirin. “If done correctly, it will help to create constancy of purpose and the development of a work culture.”

Engineers have long held a critical role in the nation’s ability to innovate, having found creative solutions to crucial problems and developed effective ways to harness technologies to put previously impossible accomplishments within reach. So, it isn’t unreasonable to expect the greatest capacity for innovation will be in areas with sizeable concentrations of engineers.

Engineers have long held a critical role in the nation’s ability to innovate, having found creative solutions to crucial problems and developed effective ways to harness technologies to put previously impossible accomplishments within reach. So, it isn’t unreasonable to expect the greatest capacity for innovation will be in areas with sizeable concentrations of engineers. In our ongoing series of posts highlighting companies that have taken extra steps to satisfy Occupational Safety and Health Administration (OSHA) safety requirements in their

In our ongoing series of posts highlighting companies that have taken extra steps to satisfy Occupational Safety and Health Administration (OSHA) safety requirements in their  In the 1880s, freight cars became a popular way to transport agricultural products from the farms to the market. Transporting goods by rail remains one of the most cost and energy efficient ways to move bulk quantities of raw materials today. Modern freight cars are not only capable of containing a tremendous volume of goods such as sugar and limestone, but also hauling a great deal of weight – up to 120 tons!

In the 1880s, freight cars became a popular way to transport agricultural products from the farms to the market. Transporting goods by rail remains one of the most cost and energy efficient ways to move bulk quantities of raw materials today. Modern freight cars are not only capable of containing a tremendous volume of goods such as sugar and limestone, but also hauling a great deal of weight – up to 120 tons! Today’s increasingly conscience-focused marketplace and workplace demands more ethical business processes and performance than ever. As such, it’s no surprise that a 2012 paper by the Center for Creative Leadership (CCL) indicates that integrity is the key criteria in determining success by top executives. “Interestingly, however, integrity is not the key criteria for success by middle managers according to performance ratings. For them, the study indicates that social intelligence – understanding the people and situations around them – is key,” the Globe & Mail says of the CCL paper’s findings. “And this means many organizations, when promoting their best middle managers to the executive suite, may be putting their weight behind people whose integrity has not yet been tested – and may even be missing.”

Today’s increasingly conscience-focused marketplace and workplace demands more ethical business processes and performance than ever. As such, it’s no surprise that a 2012 paper by the Center for Creative Leadership (CCL) indicates that integrity is the key criteria in determining success by top executives. “Interestingly, however, integrity is not the key criteria for success by middle managers according to performance ratings. For them, the study indicates that social intelligence – understanding the people and situations around them – is key,” the Globe & Mail says of the CCL paper’s findings. “And this means many organizations, when promoting their best middle managers to the executive suite, may be putting their weight behind people whose integrity has not yet been tested – and may even be missing.”

One of the worst-case scenarios for a business owner is an industrial accident causing property damage or personal injury to workers. One possibility could be an industrial accident caused by combustible dust, or tiny airborne particulates that can suddenly explode under the particular circumstances.

One of the worst-case scenarios for a business owner is an industrial accident causing property damage or personal injury to workers. One possibility could be an industrial accident caused by combustible dust, or tiny airborne particulates that can suddenly explode under the particular circumstances. Rising global demand – As the global economy heals, demand for American-made products is picking up. In fact,

Rising global demand – As the global economy heals, demand for American-made products is picking up. In fact,  An explosion that injured a worker in a British Columbia sawmill in July could have had much more devastating results if it weren’t for the facility’s diligence in cleaning combustible dust, the mill owner said.

An explosion that injured a worker in a British Columbia sawmill in July could have had much more devastating results if it weren’t for the facility’s diligence in cleaning combustible dust, the mill owner said.