Risk, unpredictability and even failure are unavoidable in the process of innovation. In fact, a key part of the innovation process is the ability to experiment, process failures, learn from them and turn them into beneficial experiences.

Risk, unpredictability and even failure are unavoidable in the process of innovation. In fact, a key part of the innovation process is the ability to experiment, process failures, learn from them and turn them into beneficial experiences.

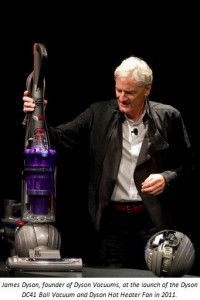

In a recent Q&A with the Chicago Tribune, Dyson Ltd. CEO Max Conze offered some insight into company founder James Dyson and the roles of both experimentation and failure in the innovation process.

Today, one-third of Dyson’s 4,500 employees are engineers, who are encouraged to look at problems that are often ignored by others and the available solutions, which are “pretty frustrating.”

“Our approach is best described as problem solving,” Conze told the Tribune. “James and everyone is a big believer in, you pose a problem, you think about possible solutions, and you prototype that solution, and then you iterate, you iterate, you iterate.

“So often the first time that the engineers think about a solution, it may literally be as crude as taking some paper and some tape and just building something and saying, if it looked like this and did this, wouldn’t that be great?” Conze continued. “And then we’ll take it into 3-D printing, and we iterate and iterate, we iterate.”

Of course, just as innovation requires taking some risks, trying something new always involves some level of uncertainty. The new idea or next iteration might work or it might not. Learning from failure is a key part of the innovation process.

“If you want to invent, you have to live through failure,” Conze said. “How many failures does it take before success?”

James Dyson is familiar with both innovation success and failure. Before his company became famous for designing and manufacturing innovative vacuum cleaners, hand dryers, bladeless fans and more, the industrial designer famously created 5,127 prototypes of his first machine, the vacuum cleaner, in a workshop behind his house, before successfully developing one that he believed worked to his standard.

“I think that’s the spirit that we’re instilling in young engineers: You’ve got to go after ideas, stay with them, failure is good,” Conze told the Tribune. “For every great machine that we can come up with, there’s hundreds of prototypes that we have discarded and thrown away along the way.”

For more information on industrial vacuum filters, including how to select the right media for the material you are picking up, please contact us or visit the DEMARCO Vacuum Accessories page.

Leave a Reply

You must be logged in to post a comment.